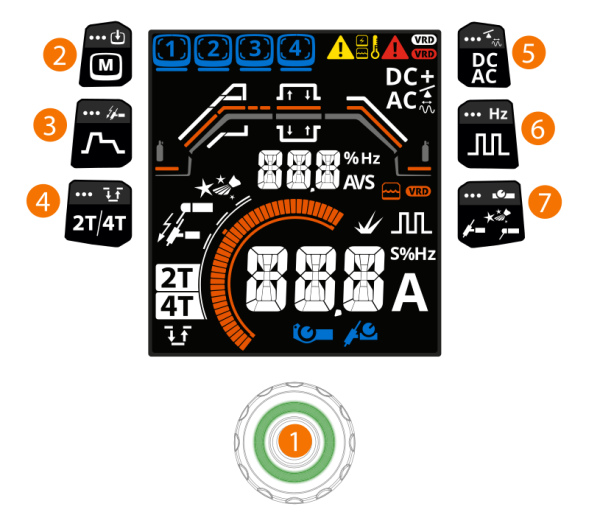

Minarc T 223 ACDC control panel

This section describes the controls and features of the Minarc T 223 ACDC control panel.

You can access different parameter adjustments and setups by pressing the physical buttons (2-7 in the figure below). Once the adjustments have been made, exit by pressing the same button again or by pressing another button.

General

| 1. | Control knob |

>> Adjustment and selection (for more information, refer to Main view)

| 2. | Memory channels button |

>> Short press: Changes memory channel

>> Long press: Saves parameters to memory channel

| 3. | Welding parameters and TIG HF ignition button |

>> Short press: Welding parameter adjustment

>> Long press: Toggles between TIG HF ignition ON / OFF (with AC TIG, the HF ignition is always on)

| 4. | Trigger logic button (TIG, cleaning and polishing processes) |

>> Short press: Toggles between 2T and 4T trigger logic functions

>> Long press in 2T: Sets 4T and Minilog on

>> Long press in 4T: Sets Minilog on

>> Short press when Minilog is on: Sets Minilog off and changes trigger logic to 2T

>> Long press when Minilog is on: Sets Minilog off but trigger logic stays in 4T

| 5. | Current mode button |

>> Short press in TIG: Toggles between DC- and AC current modes

>> Long press in AC current mode: AC balance adjustment

>> Short press in AC balance adjustment mode: AC frequency adjustment

>> Short press in MMA: Toggles between DC- and DC+ current modes

| 6. | Pulse TIG button |

>> Short press: Toggles between pulse TIG welding ON / OFF

>> Long press when pulse TIG is on: Pulse frequency adjustment

| 7. | Process and remote control button |

>> Short press: Toggles between TIG, MMA, cleaning and polishing processes

>> Long press: Toggles between remote control modes (hand/foot pedal remote, torch remote and remote control OFF). A remote control must be connected to the welding device or welding torch.

Factory reset

To reset the device to factory settings, long-press the Trigger logic button (4) and the Process and remote control button (7) simultaneously.

Symbols

| Symbol | Description |

|---|---|

|

Yellow: Warning Red: Error |

|

Power source error |

|

Cooling unit Yellow: Cooling unit error Orange: Cooling unit is on |

|

High temperature indicator (overheating) |

|

VRD (Voltage Reduction Device): White VRD symbol is on = VRD is on Red VRD symbol is blinking = There is a problem with VRD |

|

TIG welding process |

|

AC TIG balance |

|

AC frequency |

|

Pulse TIG process |

|

Pulse TIG frequency |

|

MMA welding process |

|

Cleaning process |

|

Polishing process |

|

Minilog |

|

HF ignition |

|

Arc force (MMA) |

| AUT | Auto |

| Err | Error |

|

Remote control (hand / foot pedal) |

|

Torch remote control |

|

After each weld, a weld summary (Weld data) is displayed for 5 s. |

To update the control panel software, contact your local Kemppi service.